100% Oil-Free Class ZERO Air Quality

VARIABLE AIR OUTPUT

The most efficient in its range:

- Energy Saving with Pressure Switch Control

- Low Starting Amperage

- Air Demand over 3 Shifts

HYGIENE AND SAFETY

- In oil lubricated air compressors, Oil mist in compressed Air mixes with Water and Dust to form an OIL-WATER-DUST emulsion.

- This emulsion accumulates in the compressed air piping may encourage Bacterial or Fungal Growth.

- Prolinged accumulation may encourage Bacterial or Fungal Growth.However, 100% oil free air compressors deliver compressed air without any risk of contamination.

PRODUCTIVITY AND PROFITABILITY Adhesion of Oil-Water-Dust Emulsion to high precision Bearings, Actuators, Solenoid Valves etc, may cause productivity loss due to In-process rejection, Machine Breakdown, or both. Using Oil free compressors can prevent such process breakdown & rejections.

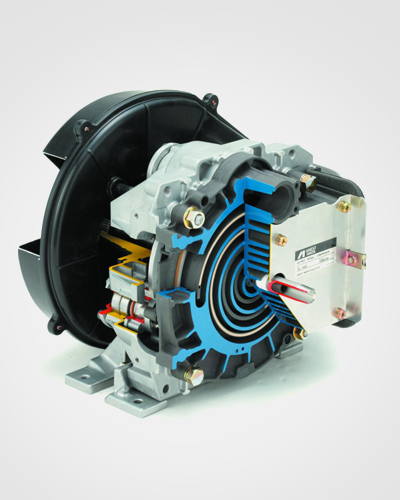

SILENTOil-free scroll mechanism has very small torque fluctuation as well as low noise and vibration.

COMPACTModels up to 5HP (3.7kW) have the same footprint as a newspaper page.

NO DRAIN TREATMENT NECESSARY Drainage from oil-lubricated compressors requires proper treatment as it contains oil. Oil-free scroll compressors on the other hand are eco-friendly, their drain is clean and does not contain oil, therefore avoiding the cost of drain disposal.